03Process of Works & Equipment

Uchino Latest Technology

Uchino Latest Technology 1 :

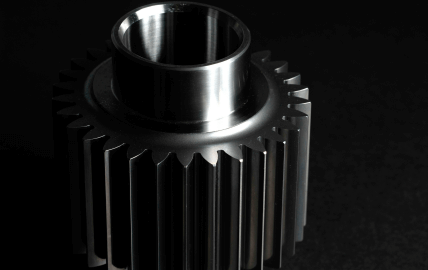

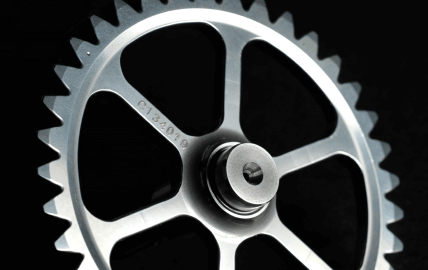

Bevel Combination Gear

Leading-edge Bevel Gear Cutting

It allows various types of high quality & sophisticated bevel gears to be produced.

Gleason bevel gear processing / polishing machine and precision measuring instrument

Gleason's bevel gear processing and polishing machine introduced by Uchino Manufacturing in 2017 is a state-of-the-art machine capable of making the highest quality bevel and hypoid gears by cutting and grinding.

Bevel and hypoid gears are often parts subjected to high torque and require advanced processing technology because of their complicated shapes.

There are two ways to make these types of gears: (1) using a hob or (2) utilizing a grinding machine with special grinding stones. Uchino machines use the latter method.

The advantage of this is the ability to quickly respond to sensitive designs by different programing and operations.

The dedicated measuring instrument is a state-of-the-art ultra high performance tester for spiral, hypoid and bevel gear sets of almost all axes shapes..

The accuracy of bevel/hypoid tooth shape, tooth contact (surface engagement), actual operating condition as well as oscillation frequency can be measured and output on graph. As far as design tolerance is concerned, it is possible to measure up to submicron units.

The measuring instrument, in collaboration with the finishing machine, make it possible to meet the design requirements of difficult to process bevel and hypoid gears of the finest quality in the world.

Uchino Latest Technology 2 :

Barrel Polisher

The Latest Barrel Finisher

The final polishing of gear parts requires the ultimate in smoothness.

Rösler barrel polishing machine

Rosler’s polishing machines are used by the world’s leading metalworking companies. They are very precise machines which use polishing media exclusively for each part. An excellent removal of polished metal by it’s drainage system enables extremely advanced finishing without contacting other parts simultaneously. In accordance with the requirements of each part, Uchino Manufacturing further polishes the metal surface with the Rösler drag finisher after working with the dentition. Following its introduction in 2017, Uchino later introduced a finisher that makes it possible to final polish longer shaped items. This makes it possible to finish grinding not only gears but also components of a wide range of complicated shapes such as shafts.

Uchino Latest Technology 3 :

Electrical Discharge Machining

Advanced Electric Discharged Machine

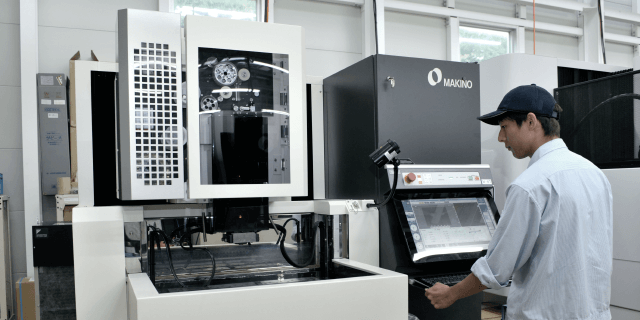

Recent introduction of new generation NC & wire electric discharge machines.

Makino NC Electric Discharge and Wire Electric Discharge Machines

In 2018, Uchino Manufacturing introduced the latest Makino NC Electric Discharge Machine as well as the Wire Electric Discharge Machine. Both have superior operation capabilities which allows for better processing capacity. Precision has improved drastically and difficult processing can be done in a shorter time.

In particular, the new NC discharge machine can process longer parts and process multiple parts at the same time. This has dramatically improved efficiency and the range of processing.