03Process of Works & Equipment

Uchino Latest Technology

Uchino Latest Technology 1 :

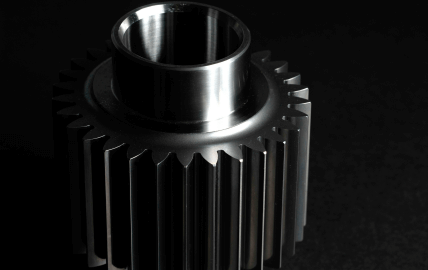

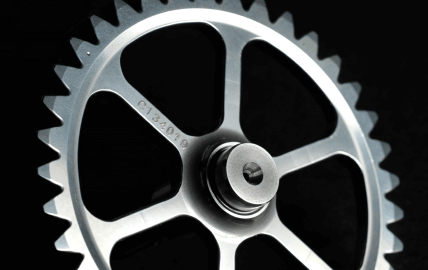

Bevel Combination Gear

Leading-edge Bevel Gear Cutting

It allows various types of high quality & sophisticated bevel gears to be produced.

Gleason Phoenix 280G

In 2017, Uchino Manufacturing Co., Ltd. introduced the Gleason Phoenix 280G, a cutting-edge high quality bevel and hypoid gear grinding machine.

In general, bevel and hypoid gears are subjected to high torque and require highly accurate machining.

There are two ways to make bevel and hypoid gears: (1) using a hob or (2) utilizing a grinding machine with special grinding stones. The 280G uses the latter method.

The advantage of this is the ability to quickly respond to sensitive designs by different programing and operations.

Products can be cut with graduated depths or heights.

We are able to provide clients with high quality and high dimensional bevel and hypoid gears very quickly due to the introduction of this machine in collaboration with the newest Gleason tester 360T and inspection machine 350GMS.

Gleason 360T

The Gleason 360T is a state-of-the-art testing machine for spiral, hypoid and bevel gears.

This tester can measure, digitize and output the vibration frequency under actual operating conditions of bevel/hypoid gears.

We are able to process gears with less noise and more efficient transmission due to accurate gear engagement which is essential for bevel/hypoid gears.

Gleason 350GMS

We introduced the Gleason 350GMS with the previous two machines above as an inspection machine for checking accurate forms and shapes of bevel/hypoid gears. The accuracy of gear teeth up to 350mm in diameter and with a tolerance value of within 1/10th of a micron can be measured.

With Gleason’s new generation inspection testing, the newest software allows for 40% quicker and even more accurate data.

Uchino Latest Technology 2 :

Barrel Polisher

The Latest Barrel Finisher

The final polishing of gear parts requires the ultimate in smoothness.

Rösler Drag Finishing Machine

Rosler’s polishing machines are used by the world’s leading metalworking companies.

This ultimate polish finisher uses special polishing medias designed exclusively in accordance with the design requirement of each part. The final polish is carried out after grinding to finely arrange the metal surface.

We recently introduced another polish finishing machine for long objects.

This allows final polishing of a wide variety of objects with complicated shapes such as shafts as well as gears.

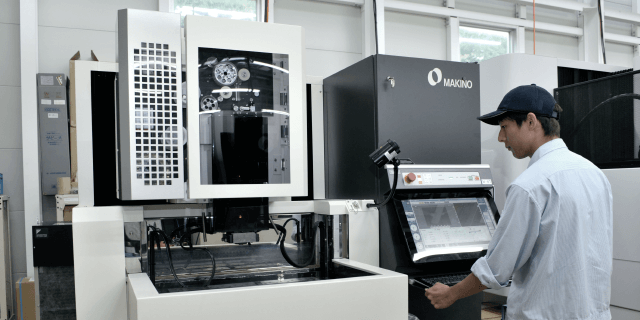

Uchino Latest Technology 3 :

Electrical Discharge Machining

Advanced Electric Discharged Machine

Recent introduction of new generation NC & wire electric discharge machines.

MAKINO W32FB & EDNC6

In 2018, we introduced the newest MAKINO NC & wire electric discharge machines. With their new operating system, these machines allow very complex processing work to be performed more easily and quickly.

The NC electric discharge machine EDNC6 is able to process parts with lengths up to 500mm and process multiple parts at one time. This allows better working efficiency and a wide range of work to be performed.