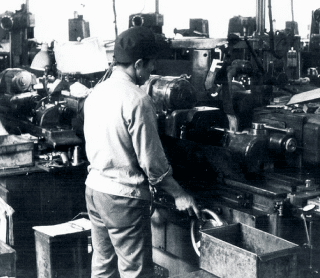

Uchino Seisakusyo was launched in 1927 by Choji Uchino as a weaving machine repair company. In 1949, the factory burned down from a World War II air raid and reopened as Uchino Seisakusyo Ltd. Soon the car industry became a key industry in Japan and second generation son Tetsuo Uchino, taking advantage of training at the European International trade fair, began production of precision gears for Honda motorcycle laboratory prototypes. The company also received orders to produce four-wheel prototype gears.

Changing jobs from a foreign lubricant manufacturer, third generation son Noriaki Uchino took over the company promoting advanced technological innovation and IT change. We focused on receiving sales and production orders of prototype gears from all two and four wheel domestic manufacturers. In 2011, for the purpose of employee working environment and better efficiency, as well as taking advantage of the natural environment, the business

was fully relocated to Hachioji Tobuki.

| 1927 |

Sep. |

Established for the purpose of repairing textile machines. |

| 1945 |

Aug. |

The factory was destroyed by fire due to war damage, and the factory was closed due to the end of the war. |

| 1949 |

Jun. |

Established Uchino Manufacturing Co., Ltd. |

| 1961 |

Apr. |

Relocated to new factory in Owada-cho, Hachioji City. |

| 1968 |

Jun. |

Changed company name to Uchino Seisakusho Co., Ltd. |

| 1981 |

Oct. |

Received an order from Honda R&D Co., Ltd. Asaka Institute for parts such as gears for the development of general-purpose motorcycles. |

| 1986 |

Jun. |

Received an order for F1 precision gears and automobile research and development gears from Honda R&D Wako Institute. |

| 1998 |

Apr. |

Noriaki Uchino was appointed as Representative Director, and Seiichi Uchino was appointed as Senior Managing Director. |

| 2011 |

Nov. |

Head office relocated to Tobuki-cho, Hachioji City. |

| 2014 |

Jun. |

Third phase construction of the head office building with 300 solar photovoltaic panels installed. |

| 2016 |

Apr. |

Introduced a production system using barcodes to improve operational efficiency. |

| Jun. |

Introduced a German-made barrel finishing machine to allow tooth surface polishing. |

| Aug. |

Introduced an Italian-made optical measuring machine for shaft parts (to allow optical measurement of shaft systems). |

| Dec. |

Introduced the Swiss-made precision grinder Studer S131. |

| Dec. |

Introduced the G280 bevel gear processing machine manufactured by Gleason in the United States. |

| 2017 |

Mar. |

Introduced Swiss-made precision grinder Studer S41. |

| Mar. |

Introduced Fujikoshi helical broaching machine. |

| Jul. |

Introduced cylindrical grinder OGM390NC manufactured by Okamoto Kogaku. |

| Jul. |

Introduced the Okamoto Kogaku PRG6DXNC surface grinder. |

| Nov. |

Introduced the Mori Seiki CNC lathe NLX2500/700. |

| Nov. |

Introduced the Mori Seiki CNC lathe NLX2500/1000Y. |

| Dec. |

Introduced an Italian optical measuring machine for shaft parts. |

| 2018 |

Mar. |

90th anniversary ceremony held at Hotel Okura Tokyo. |

| Dec. |

Introduced the Makino NC electrical discharge machine EDNC6. |

| Dec. |

Introduced the Makino wire electrical discharge machine W32FB115. |

| Dec. |

Introduced the Makino wire electrical discharge machine W32FB116. |

| Dec. |

Introduced the German made precision lathe machine G220 (Index). |

| 2019 |

Oct. |

Introduced a vibratory barrel finishing machine made in Germany. |

| 2020 |

Nov. |

Introduced a skiving machine manufactured by Gleason, USA. |

| 2021 |

Aug. |

Introduced CNC coordinate measuring machine CARL ZEISS PRISMO ultra. |

| Aug. |

Introduced a gear measuring machine made by Osaka Seimitsu Co., Ltd.. |

| Sep. |

Akiruno Factory begins operation (Ushinuma, Akiruno City). |

| 2022 |

May. |

Introduced the German KAPPVX59 composite gear grinder. |

| Jul. |

Introduced the German KAPPVX59 composite gear grinder. |